Comparison of tumbler and Teeco flat panel style tent washing machines

Teeco Solutions is the leading manufacturer in machines to wash PVC tent and Marquee tops. There are two styles of machines available for your tent and marquee washing needs; a tumbler style washer and a flat panel style washer. There are over 15 machines available to deliver the results you need. Your business is unique and each machine is designed to deliver different results. You have the opportunity to not only get a machine that will change the way your business operates, but also that will revolutionize the business you have built. As a start to understanding the correct machine for your business, take a look at the comparison charts below. Once you get an understanding of the differences between a flat panel washer and a tumbler washer, the next step would be to allow us to work with you to select which of the 15 machines may be right for you.

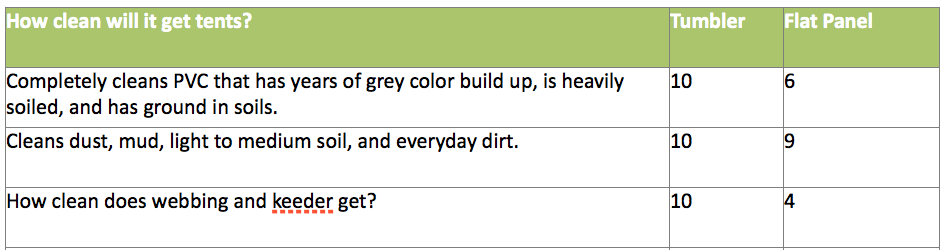

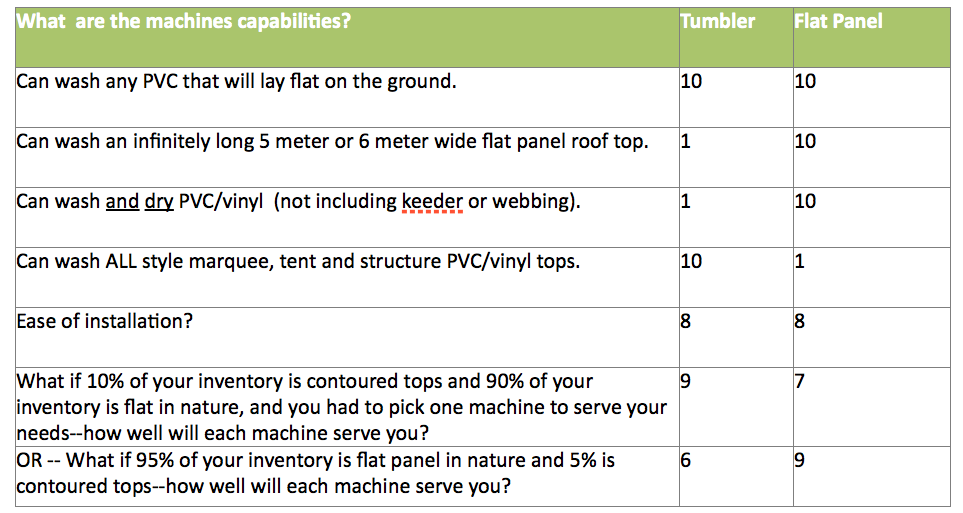

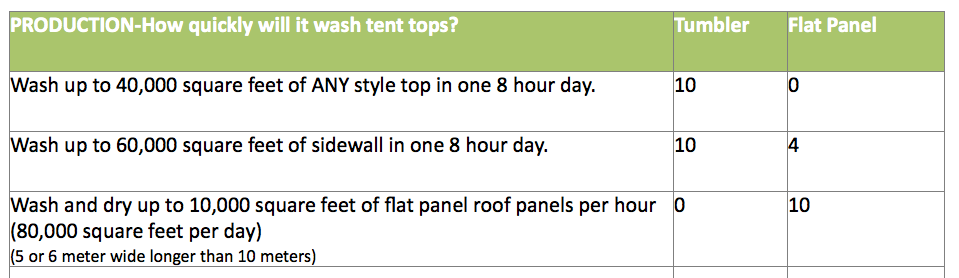

As you look at the chart below, keep in mind that a rating of 1 means the machine is not very well suited for the application and a rating of 10 means that the machine is very well suited for the application.

Summary: Flat panel washers are highly productive for inventories having greater than 90 percent flat panel. Flat panel washers are the best choice for washing a volume of 5 and 6 meter wide pieces of roof panels over 10 meters long. Tumbler washers are the best for getting the deepest level of clean. Tumbler washers will wash all style tent and marquee tops and are best suited to wash high volumes of sidewall. KEEP IN MIND: If you are currently hand washing- no matter what machine you select you will see great improvements in your operation. However , if you want to see the most optimal improvements in your operations, it is well worth your time to spend 45 minutes with us. Together we will work through a process that helps us clearly understand what you are trying to accomplish and allows us to understand your inventory, your space , your employees, your workflows and much more so that we can select and build the right machine for you.